Material Passports: Enabling regenerative practices circularity at One Nine Elms

Defying the ‘Doom Loop’

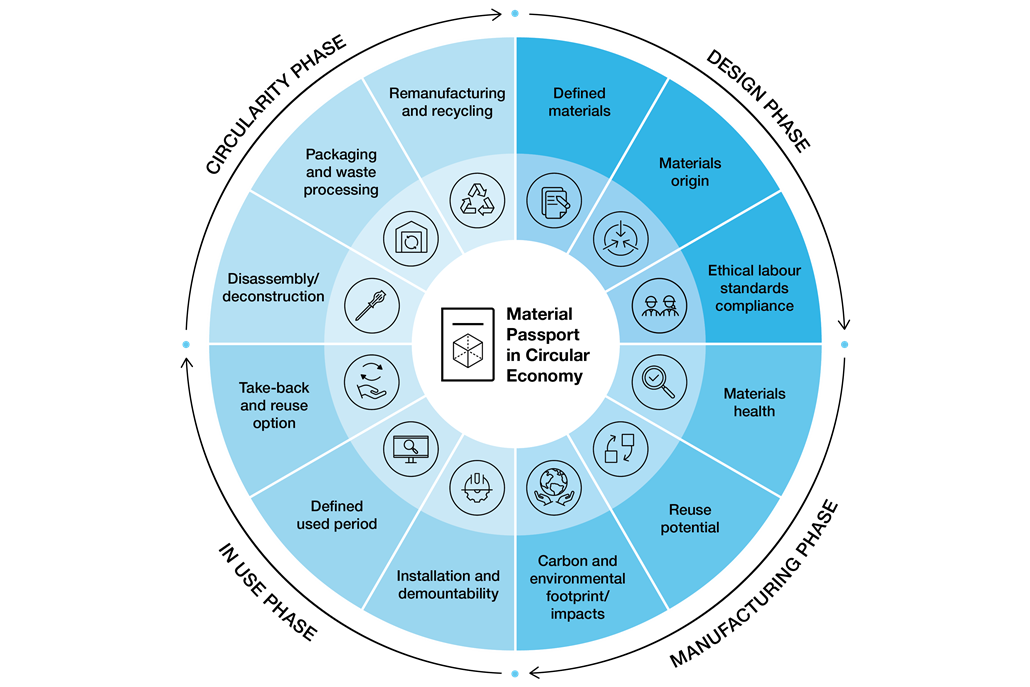

Material Passports facilitate a circular economy

The construction industry has a major role to play in the reduction of carbon emissions; at Multiplex we take this seriously and work closely with our clients and design teams to drive positive outcomes. We continuously challenge ourselves and our supply chain to improve our delivery methods. This means embracing circular practices and incorporating them into our processes as standard. Reducing embodied carbon, which accounts for roughly half of all building related carbon emissions, is a key focus. So how do we do it?

By actioning Circular Economy Theory

Material Passports, recently trialed on our One Nine Elms project, represent the future of circularity. But what is a material passport?

Material Passport: A digital identity card that details the component parts of a building, including production and performance information for the purpose of future reuse, as well as calculating the overall carbon footprint.

What does this look like in practice?

At One Nine Elms, we worked with Maconda Solutions to use innovative software from Upcyclea® to create the Material Passports. By aggregating the information from the passports assigned to products used in the building, our project team were able to generate key metrics. This data was then plugged into the smart platform, myUpcyclea®, which extracted the figures and generated scores relating to the carbon, circularity, material health and financial residual value of the project - the ‘Circular Signature®’’.

Why Material Passports?

Circularity and regenerative design are hot topics in the construction industry, because we have reached a stage where building in a climate-conscious way is the only viable route forward. Implementing a truly circular economy requires transparency, which Material Passports enable. By providing a bank of information and materials which are readily available, Material Passports represent a significant shift in the economics of construction and the wider industry mindset. Increasingly, developers are turning towards these circular methods, and Multiplex is proud to be at the forefront of progress. Reusing pre-existing elements to create new structures has a knock-on positive effect; it lessens demand for virgin natural resources, eliminates waste, reduces carbon emissions, and enables efficient disassembly. Re-using elements also encourages conscious design, extending the life cycle of a building. These are outcomes we should all be striving for and

working towards, together.

The Multiplex Way

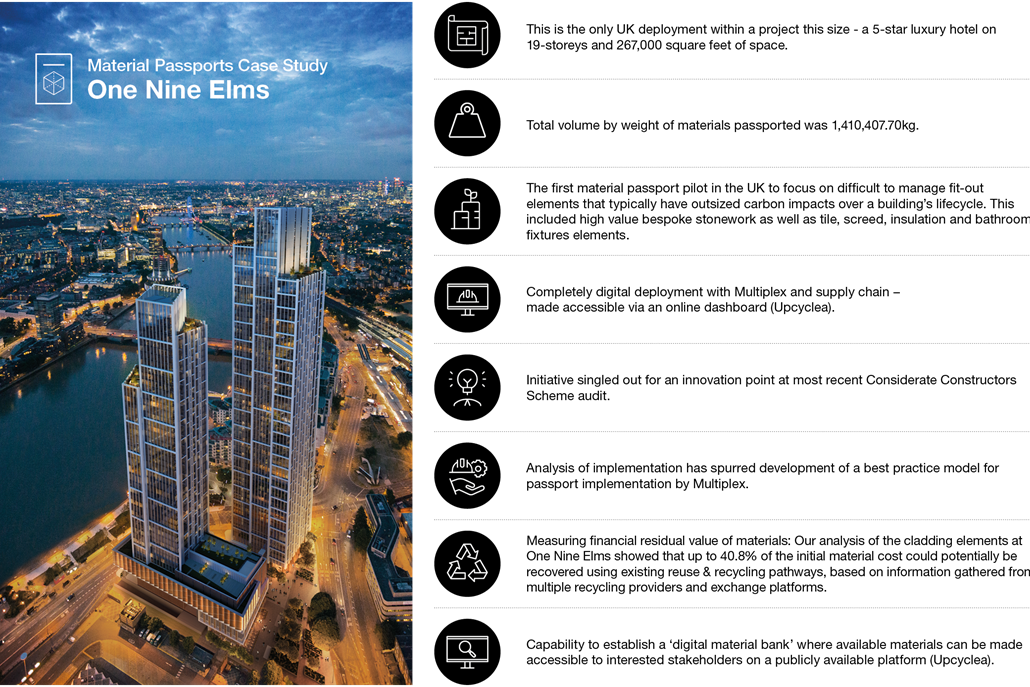

One Nine Elms is a prime example of our dedication to regenerative practices: it is our largest on-site London based project to date, and the only development of this scale in the UK that includes Material Passports certification for key elements of the project. It is also the first Material Passport pilot in Britain to expressly focus on difficult-to-manage fit out elements, which included high value bespoke stonework as well as tile, screed, insulation and bathroom fixture elements.

The Material Passports at One Nine Elms enabled the team to calculate the aggregate carbon impact of all individual items within the fit-out package, in turn demonstrating the overall carbon footprint of the structure itself. Reuse pathways and next life information is easily accessible by myUpcyclea®, which also makes clear the residual economic value of the building based on the recoverable income from the re-sale of used products or materials. This is invaluable in articulating the financial benefits of a circular economy approach to future clients. For example, analysis of the cladding elements at One Nine Elms showed that up to 40.8% of the initial material cost could potentially be recovered using existing reuse & recycling pathways, (with pricing information gathered from multiple recycling providers and exchange platforms).

At Multiplex, we are committed to being as transparent as possible, so others can learn alongside us. Throughout the Material Passports trial at One Nine Elms, we continually assessed progress, gathering data to identify and examine any practical challenges and make these findings available to the wider industry. We then presented the case study and recommendations at the industry led ORMS Material Passport Working Group, as well as at the UKGBC & ReLondon. One Nine Elms allowed us to begin developing a structured framework for Material Passport protocols which is practical and, crucially, achievable, and can be deployed by contractors on site. Our subcontractor partner on the initiative, Chiltern Contracts, was able to demonstrate how this model could be applied along the entire supply chain.

One Nine Elms proved that Material Passports can be integrated into complex projects - something the industry is increasingly moving towards. We are proud to be paving the way, and thrilled to have been recognised for our innovative practices at the most recent Considerate Constructors Scheme audit.